Home » Installation » Hybrid flooring installation » Instructions » How to install hybrid flooring with integrated underlay? Installation instruction

Hybrid flooring is becoming increasingly popular thanks to its durability and moisture resistance, making it an ideal solution for a variety of rooms. In this article, we’ll explain how to properly install a hybrid floor with an integrated underlay to ensure its stability and longevity.

1.

Before the floor is delivered to the installation site, doors and windows must be installed in the building, and all “wet” work must be completed, e.g. plastering, partition wall construction, painting, etc. If there are basements under the floor installation site in the building, they must be dry and well ventilated. Hybrid floors can be installed in all living areas such as rooms, bedrooms, kitchens and most public spaces.

Important:

Hybrid boards with integrated underlay cannot be installed using an adhesive system.

Hybrid boards with an integrated underlay can only be installed in a floating system.

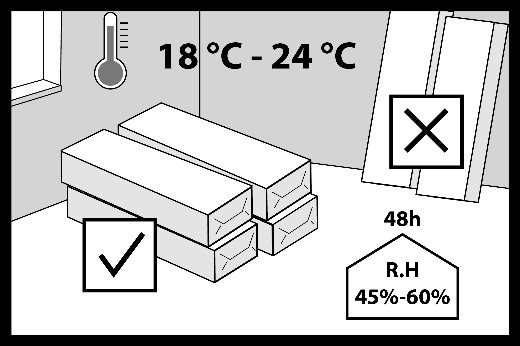

Packages containing hybrid boards should be handled with care during transport and unloading to avoid any mechanical damage. Hybrid boards should be stored in their original packaging in a dry place, in a horizontal position, on pallets or wooden beams. There must be at least 75 mm of free space between the hybrid boards and the floor. Hybrid boards should be stored in their original packaging in the room where they are to be laid for at least 7 days.

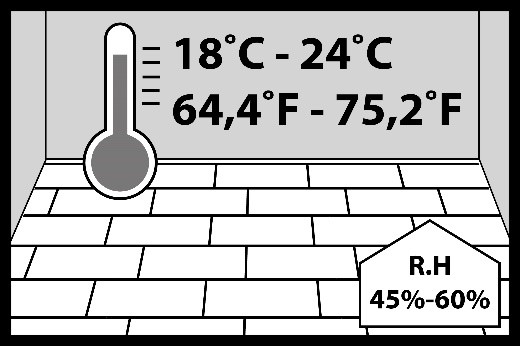

75 mm between the hybrid board package and the ground. Hybrid boards should be stored in their original package in the room where they are to be laid for at least 48 hours to allow them to acclimatise. The air temperature should be between +18°C and +24°C. Relative air humidity between 45% and 60%.

2.

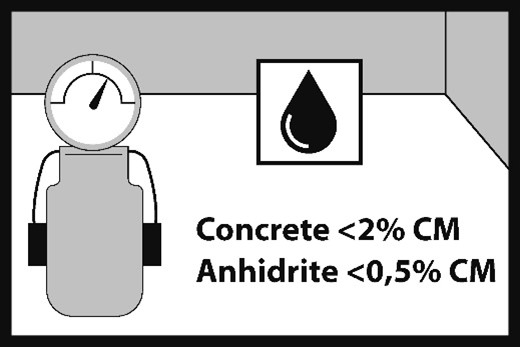

The moisture content of the wooden substrate (or wood-based panels) should not exceed 12%. The moisture content of concrete substrates without underfloor heating systems should not exceed 2%, and that of anhydrite substrates should not exceed 0.5%. The measurement results should be documented.

3.

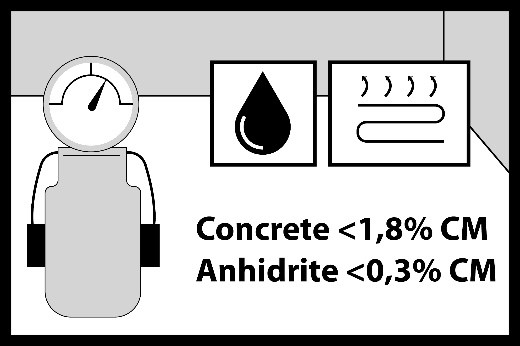

When installing hybrid boards on underfloor heating, the moisture content of the concrete substrate should not exceed 1.8%, and that of the anhydrite substrate should not exceed 0.3%. The measurement results should be documented.

4.

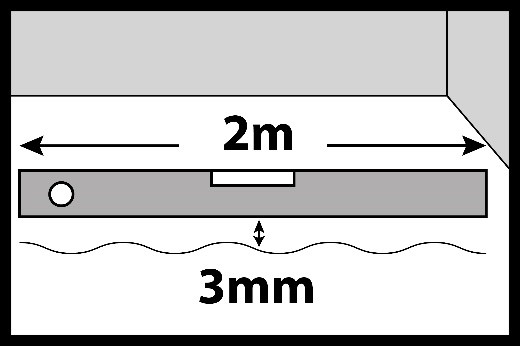

The maximum acceptable unevenness may be up to 3 mm, measured over a length of 2 m. Local unevenness should not exceed 2 mm over a length of 1 m.

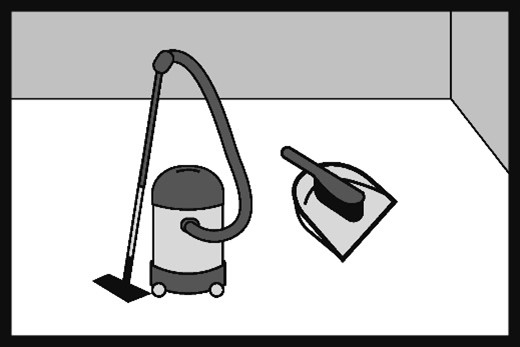

5.

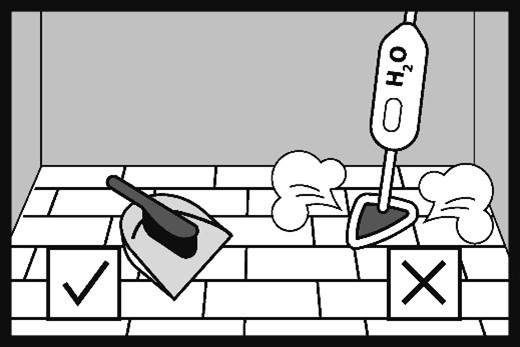

Before starting the installation of hybrid boards, sweep or vacuum the substrate. The substrate should be free of dust, debris, paint, lacquer, wax, grease, oil, hardeners, sealants, solvents, sand, adhesive residues, grease, and other foreign matter.

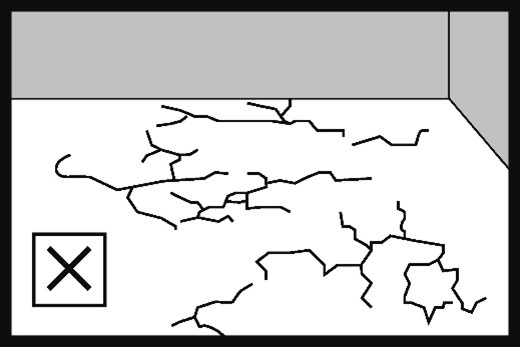

6.

The substrate should be dry, stable, free of scratches and cracks, and clean with no visible dirt. Cracks

and defects in the cement or anhydrite substrate should be filled. When installing on ceramic tiles, joints wider than 5 mm and deeper than 2 mm

must be filled.

Plywood, OSB board and chipboard must be structurally sound and installed in accordance with the board manufacturer’s recommendations. We recommend installing wood-based boards in two layers, joined with wood screws. The edges of one layer of board should be installed in a staggered manner in relation to the second layer. The wood-based board substrate must provide adequate rigidity and support for the proper installation of the hybrid floor. The board joints should be smooth and should not deflect or spring under load. All screw heads should be slightly countersunk below the board surface.

7.

Hybrid boards must not be installed on existing soft carpet coverings, soft PVC coverings, carpets or other similar materials.

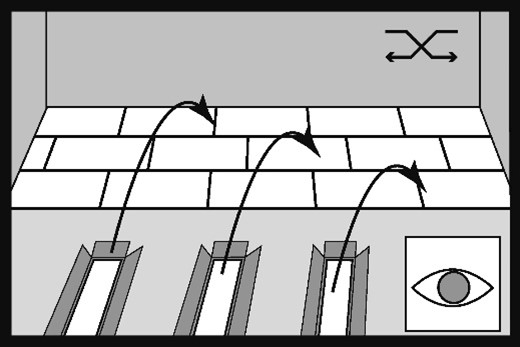

8.

During installation, hybrid boards should be installed from several packages , matching them in colour to achieve a balanced visual effect of the floor.

When ordering flooring, order approx. 3% more boards than the measured surface. Where there are many angles in the room or obstacles, hybrid boards are installed diagonally across the room or at joints with ceramic tiles, and approx. 10% extra may be required.

9.

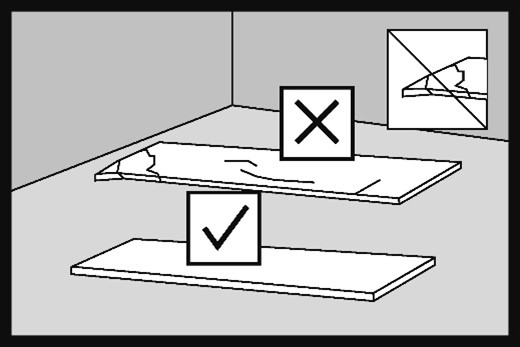

Before installation, the investor or installer should check the hybrid boards and verify that they comply with the order.

The boards should be checked for quality, finish, gloss, colour and mechanical damage (all information can be found on the label, instructions or product card). In case of doubt, the investor or installer should not use any hybrid board that they consider unsuitable for installation and should immediately contact the seller. Installation of a damaged hybrid board that does not comply with the order, has visible defects or unacceptable optical characteristics will result in the loss of the Warranty.

10.

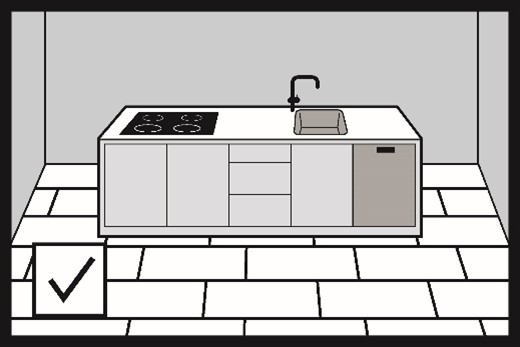

Heavy objects such as kitchen islands and furniture can be placed on the floor without the need for expansion joints around the fixtures.

However, it is necessary to make a perimeter expansion joint around fixed elements connected to the floor, e.g. plumbing and sewage systems.

11.

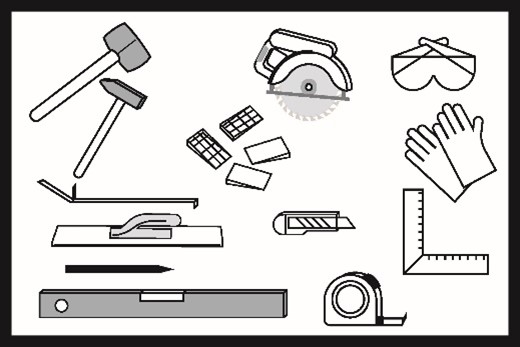

Recommended tools and materials for floor installation:

Cutting knife

12

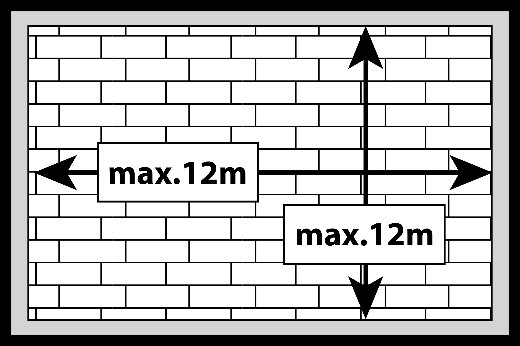

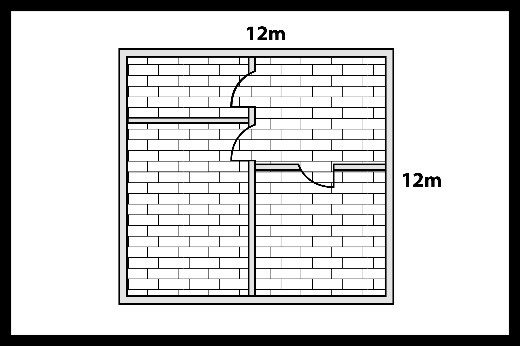

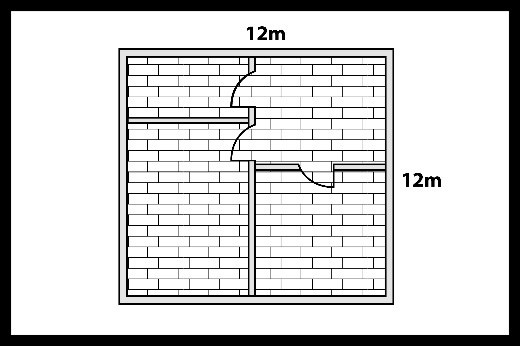

The maximum dimensions of a floor plan of a house/flat where a floating hybrid floor does not require expansion joints in doorways are 12 m x 12 m.

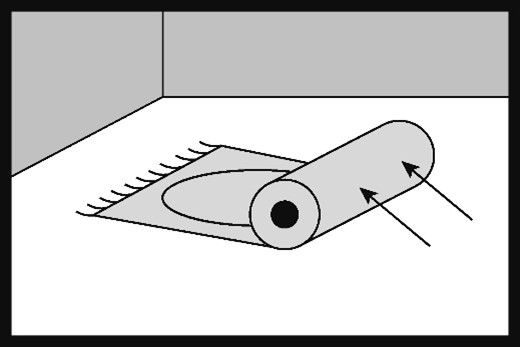

13.

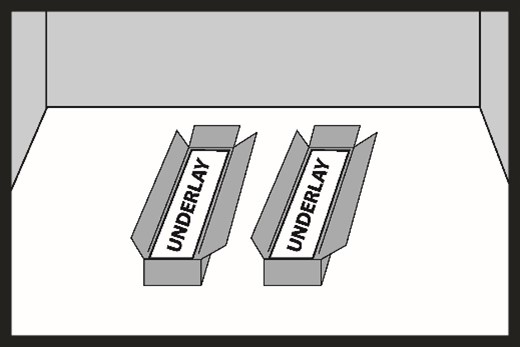

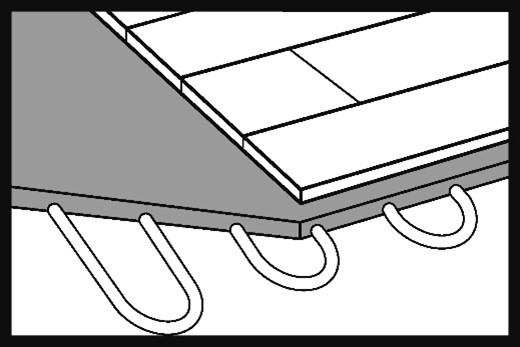

The hybrid board has a 1 mm thick XPO foam underlay glued to its underside.

CS base parameter – short-term load≥ ,400 kPa.

The underlay integrated with the hybrid board with these parameters will withstand various types of loads throughout the entire lifetime of the floor.

IMPORTANT:

No additional underlay is required.

14.

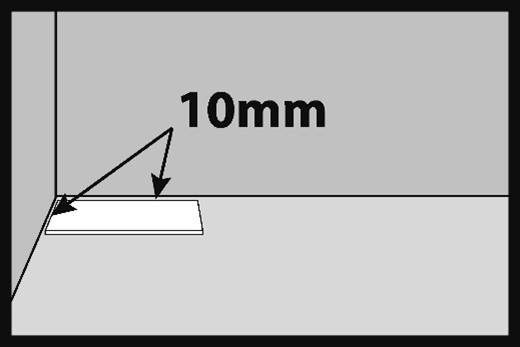

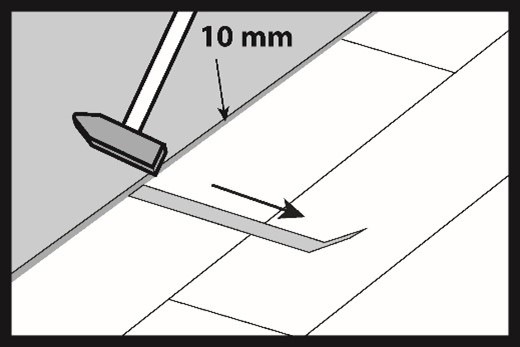

Start installation on the left side of the wall and continue to the right. The expansion gap should be at least 10 mm. Expansion wedges will help to maintain the same gap size. The expansion gap should be made along the perimeter of the room and around any other obstacles such as posts, stairs, ceramic tiles, etc.

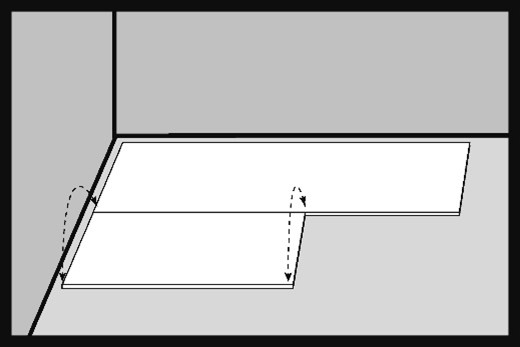

15.

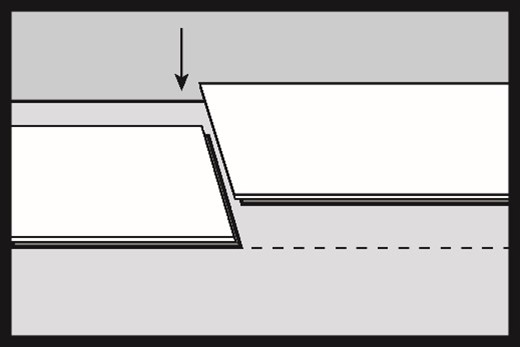

Place the short edge of the second hybrid board against the edge of the first board. Make sure that the edges are precisely aligned. The connected boards must be precisely aligned in a straight line.

16.

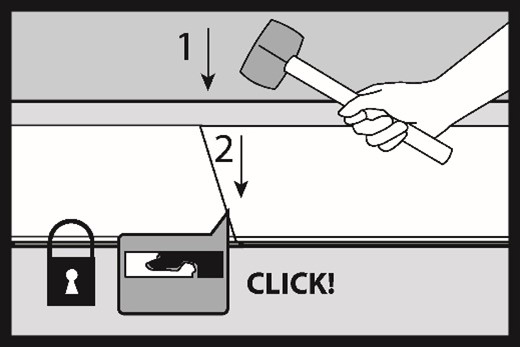

Gently tap the edge connection with a rubber mallet and fasten the lock in the order of tapping 1 and 2. When the lock is fastened correctly, the surface layer of the boards should be flush and there should be no visible difference in level between the connected elements.

17.

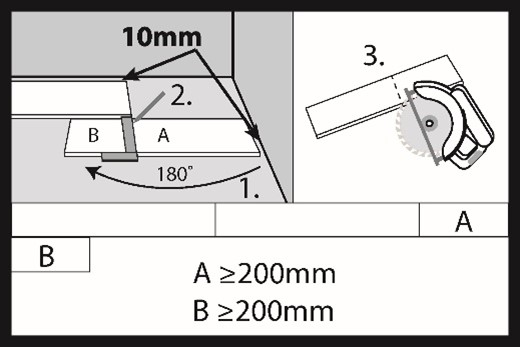

A hand saw or electric saw can be used to cut hybrid boards. Remember to leave an expansion gap of at least 10 mm after cutting the last hybrid board. The recommended length of the last cut board (A) in the first row of flooring should be at least 200 mm. If the cut piece (B) is longer than 200 mm, it can be used to start installing the second row of flooring. The distance between the end joints in two adjacent floor strips should be at least 200 mm.

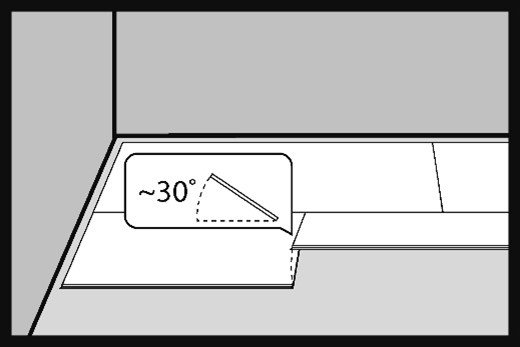

18.

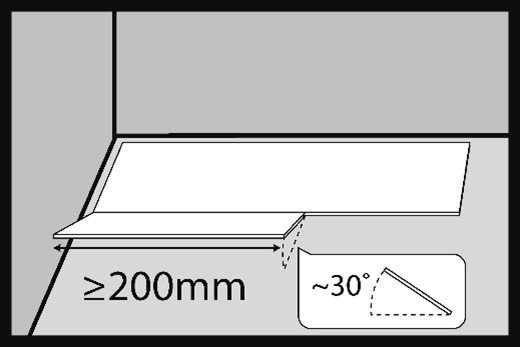

Insert the first hybrid board in the second floor strip at an angle of approx. 30° into the lock of the board in the first floor strip.

The minimum length of the board being installed should be at least 200 mm.

19.

If the board does not fall freely during installation, tilt it alternately up and down and press it lightly.

20.

Tap the board on the long side with a tapping block. When installing hybrid boards, always tap the locks on the long side.

21.

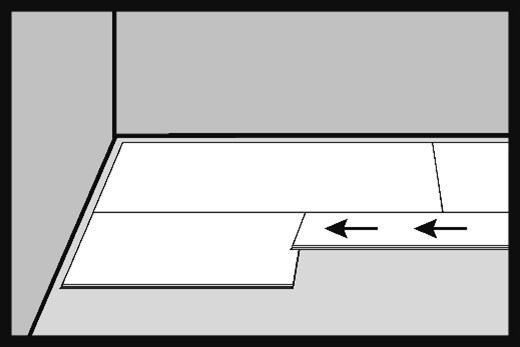

Insert the second board in the second row of the floor at an angle of approx. 30° into the lock of the board installed in the first row.

22.

Push the board towards you so that the short edges touch each other.

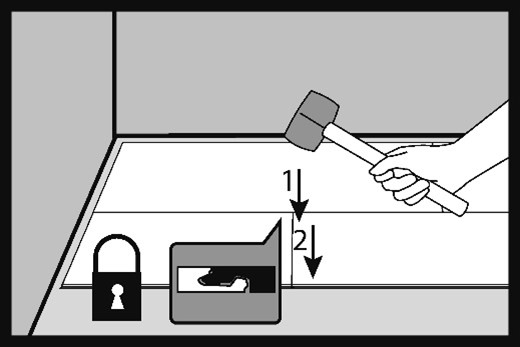

23.

After lowering the board being installed and connecting the short sides, fasten the lock by tapping with a hammer in the order 1 and 2.

24.

Tap the board on the long side with a mallet. When installing boards, always tap the locks on the long side.

25.

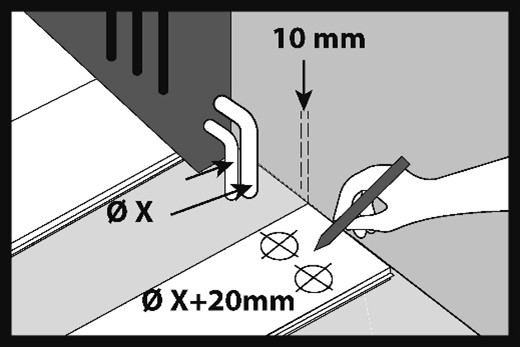

For the radiator pipes in the hybrid board, we need to draw holes with a diameter 20 mm larger.

26.

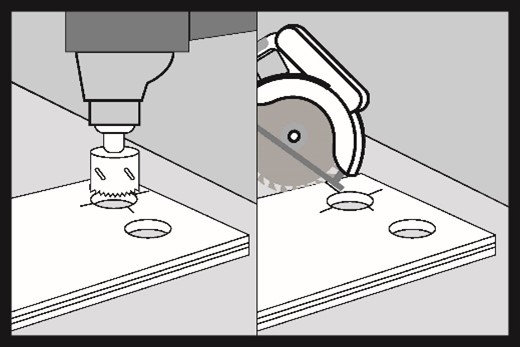

Cut the holes in the board. Draw

a line through the centre of the holes and cut the board with a saw.

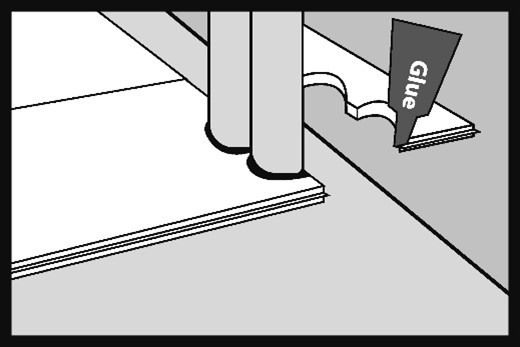

27.

Glue the cut piece of board back in place using assembly glue.

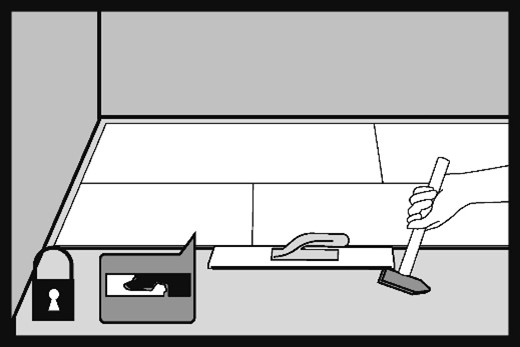

28.

Use a metal claw to hammer in the last row of hybrid boards.

29.

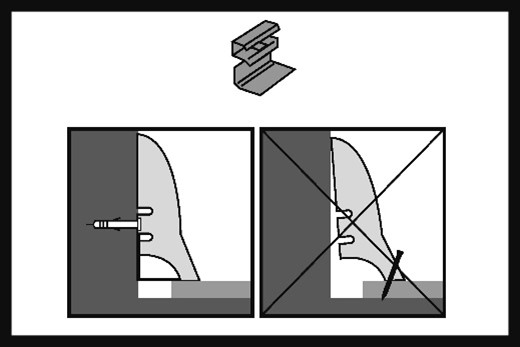

After installing the entire floor surface, install decorative skirting boards. Skirting boards should only be attached to walls using mounting clips or assembly adhesive.

30.

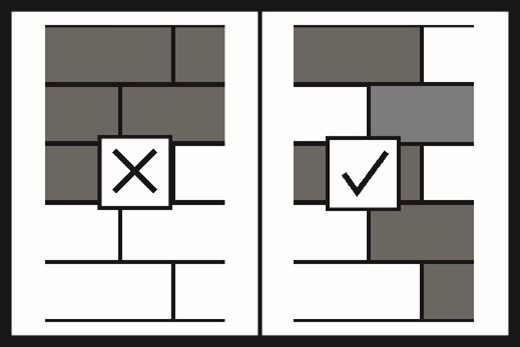

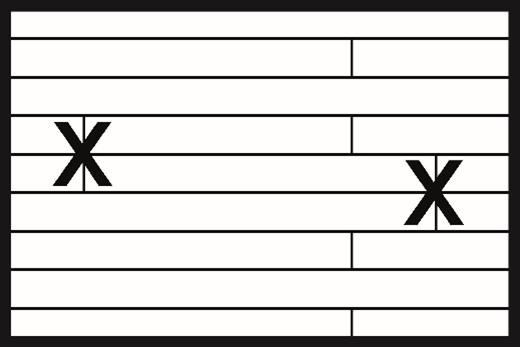

Cross joints in adjacent floor strips are unacceptable.

The minimum recommended offset of joints on the short edges of hybrid boards in adjacent floor strips must be greater than 200 mm.

31.

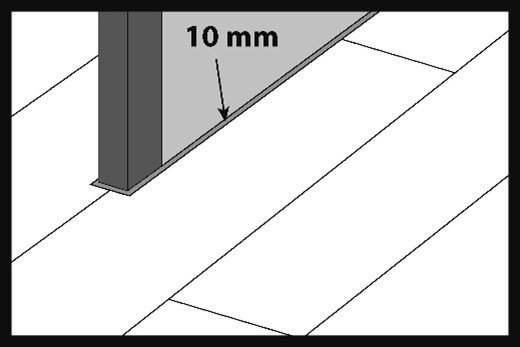

Important: There is no need to make an expansion joint in passages from one room to another. We only make it on walls and other elements permanently built into the building, e.g. stairs, columns and other obstacles. The maximum dimensions of the floor plan of a house/flat where a floating hybrid floor does not require expansion joints in doorways are

12 m x 12 m.

32

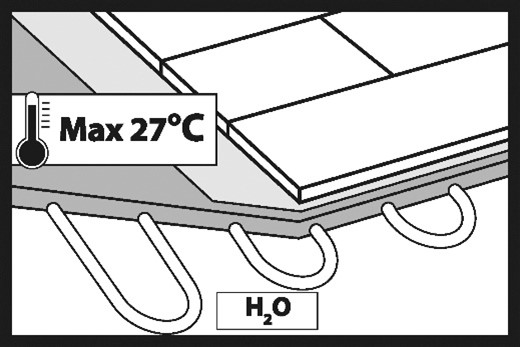

It is very important that the floor cooling system is equipped with appropriate control systems that prevent water vapour from condensing on the floor surface. To prevent this, the temperature of the cold water in the pipes should not fall below a certain value. Each room with a floor cooling system should be equipped with a sensor that calculates the relative humidity of the air in relation to the temperature on the surface of the boards and cuts off the supply of cold water before the so-called dew point is reached, i.e. the condensation of water vapour on the surface of the boards.

Thermostats in rooms should not be set to a temperature lower than 23°C. In addition, the difference between the temperature on the thermostat and the temperature in the room should not exceed 5°C. Example: room temperature 30°C, temperature set on the thermostat min. 25°C.

The floor cooling system should be protected against the water temperature in the system falling below +18°C.

The floor cooling should be switched off 48 hours before installing the floor. After installing the floor, it can be switched on again after 48 hours.

The moisture content of the cement screed should be max. 1.8% and that of the anhydrite screed max. 0.3%. Measurements should be taken using the carbide method, known as CM.

The remaining installation and usage parameters are in accordance with the installation instructions and the terms of use and care for hybrid floors. For more information, visit www.barlinek.com

The decision on the possibility of using underfloor cooling requires a heat balance to be drawn up at the design stage. Omitting this stage may lead to the incorrect selection of equipment and insufficient performance of the entire cooling system.

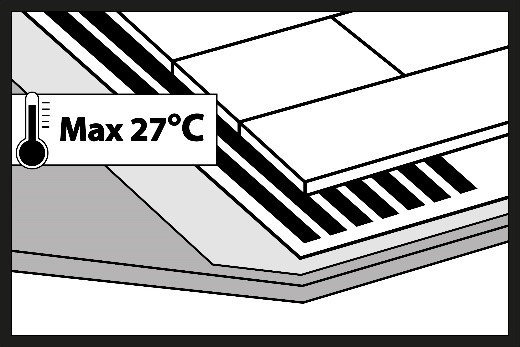

33.

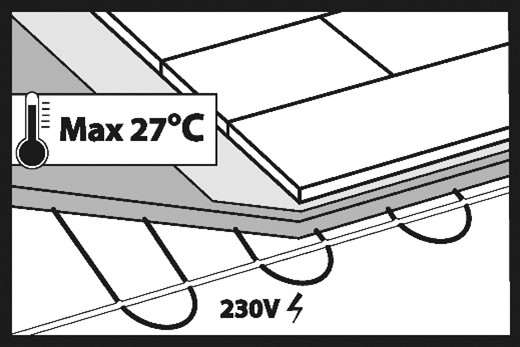

Hybrid floors can be installed on water or electric underfloor heating in a floating system.

IMPORTANT!

Before laying hybrid boards on underfloor heating , it is necessary to heat the screed and draw up a heating report. This applies only to new, unheated screeds in which the heating system is embedded. The screed heating process should also be carried out in the summer. Information on screed heating and the report are available at www.barlinek.com. If a heat pump and floor heating programme are installed, we must perform a floor heating cycle in accordance with the programme .

The maximum temperature on the surface of the hybrid floor during operation of the heating systems should not exceed 27°C.

The moisture content of the screed when installed on underfloor heating should not exceed:

To prevent uneven operation of the hybrid board core, the entire floor surface should be heated. This also ensures maximum comfort of use (no colder spots on the floor).

Floors with underfloor heating must not be covered with carpets.

Furniture placed on underfloor heating, e.g. sofas, should have legs at least 10 cm high.

Do not start the heating system during installation. During the installation of hybrid floors, the underfloor heating system must be switched off and the surface temperature of the subfloor (screed) should be between +18°C and +24°C.

The underfloor heating system should not be turned on until at least 48 hours after the hybrid flooring has been installed.

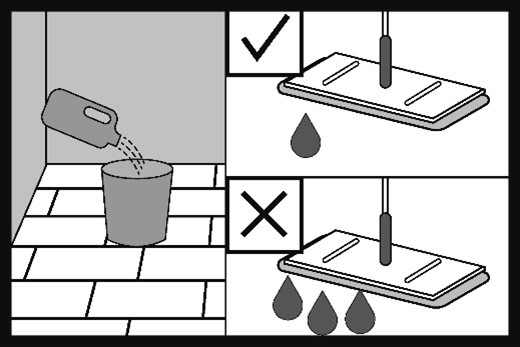

During use of hybrid floors on floors equipped with underfloor heating, please note that any liquids spilled on the floor surface may evaporate more quickly. Therefore, any stains caused by liquids such as wine, urine, milk, etc. should be removed from the floor surface as soon as possible, because if they dry on the surface of the hybrid boards, they may cause permanent discolouration of the floor.

The height of the screed over the heating elements should be at least 20 mm.

For installers – the use of thermal seals is recommended.

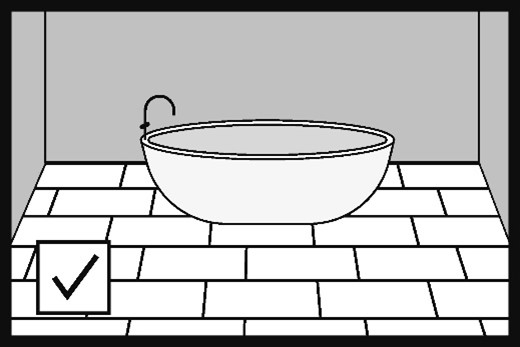

34.

Hybrid floors with integrated underlay can be installed in bathrooms and other rooms where water spillage may occur in a floating installation system.

In a floating installation system, it is essential to make an expansion gap in the frame opening with a minimum width of 5 mm (adapted to the type of masking expansion strip).

In a floating installation system, always make a 5 mm wide expansion gap around the perimeter.

In bathrooms with underfloor heating, an expansion joint must be made

in the frame opening, separating

the bathroom from other rooms.

Expansion joints must be used around walls, shower trays, bathtubs, toilet bowls and other obstacles permanently attached to the floor.

Important:

Hybrid boards must not be installed in shower trays, bathtubs, saunas, swimming pools or other similar areas exposed to prolonged contact with water.

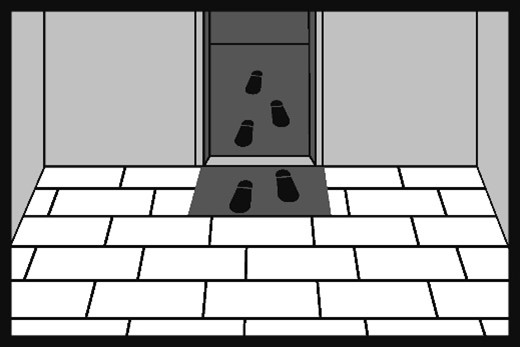

35.

Protective mats should be placed at the entrances to the apartment. Protect the floor by using mats outside and/or inside all entrances. The mats will collect dirt, sand, pebbles and other solid particles and absorb moisture. Keep the mats clean. Do not use mats with latex or rubber backing on hybrid flooring, as some compounds in these materials may permanently stain or damage the boards. Mats for use on hybrid boards should be labelled “non-staining”.

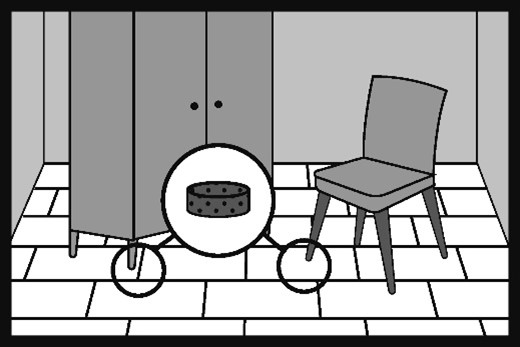

36.

All furniture and other equipment that comes into contact with the floor should be equipped with protective pads, e.g. felt pads, which should be replaced regularly.

37.

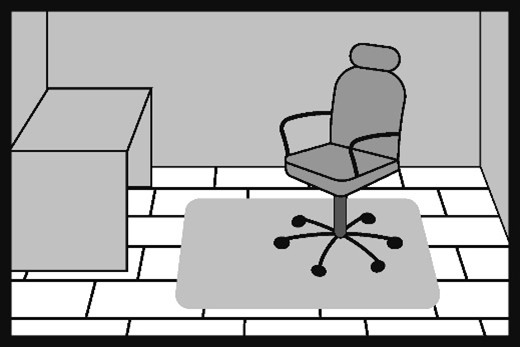

Armchairs and other furniture equipped with

with hard plastic castors should be used on plastic protective mats. If protective mats are not used, replace the castors with those designed for hard floors, type W.

38.

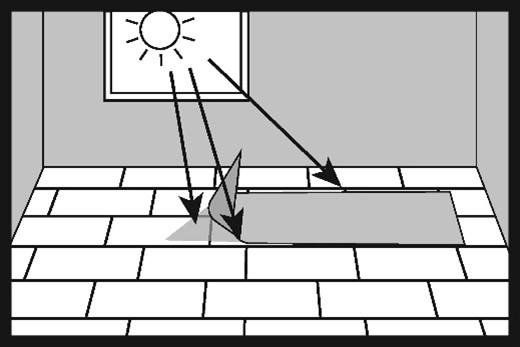

Floors exposed to sunlight (UV light) will change their original colour.

39.

The floor is factory finished

and ready for use immediately after installation.

Floor care should only be carried out using products intended for this purpose. Care instructions for hybrid floors can be found at www.barlinek.com

40.

During use, the room temperature should be between +18°C and +24°C and the relative humidity between 45% and 60%.

autor:

w całej Polsce pracują montażyści certyfikowani przez Barlinek