What are the considerations when choosing an underlay for Barlinek wooden layered floors?*

A floor made of wooden layered floorboards must meet the expectations regarding the quality and comfort of use for many years. Therefore, it is important to select the best underlay that binds the floor to the subfloor.

The underlay should have the following characteristics:

- Allow for correct installation, in accordance with Barlinek’s guidelines.

- Improve the performance of the floor, both in terms of sound proofing (reduction of foot traffic noise) and thermal comfort (underfloor heating or cooling).

- Ensure the floor is durable for many years.

Barlinek’s recommendations regarding the floor underlay specification depending on the required floor characteristics:

SUBFLOOR / STRUCTURE REQUIREMENTS

Underfloor heating, cooling (Rƛ,B)

All Barlinek wooden floors can be installed on water or electric underfloor heating systems and underfloor cooling systems. The highest efficiency of the heating / cooling system will be obtained by using under-floor underlays with the lowest possible thermal resistance (R).

The maximum allowable value of thermal resistance R for the layered floorboard + underlay system must not exceed:

For underfloor heating systems: R ≤ 0.15 m²K / W

For underfloor cooling systems: R ≤ 0.11 m²K / W

With the thermal resistance of a wooden layered floorboard of R = 0.1 m²K/W, it follows that the thermal resistance of the underlay for a layered floorboard should not exceed:

For underfloor heating systems: R ≤ 0.05 m²K / W

For underfloor cooling systems: R ≤ 0.01 m²K / W

The following underlays in Barlinek’s offer meet these requirements:

• FixMat SOUND 2.1SD

• EXTREME 1.5

Underlay without underfloor heating, cooling (Rƛ)

THERMAL INSULATION

On unheated floors, we recommend the use of substrates with higher thermal resistance. Underlays whose thermal resistance is R≥0.05 m²K/W increase the thermal resistance of the layered floorboard + underlay system, which increases the temperature on the floor surface. We recommend using underlays with high thermal resistance above unheated rooms, such as garages, basements, corridors, etc.

The following underlays in Barlinek’s offer meet these requirements:

• EKO under-floor tile

• Cork mat

Punctual conformability (PC)

Correct installation of the floor requires the underlay to level the minor unevenness of the floor. The higher the value of the PC coefficient, the better the underlay performs its surface levelling function. This parameter also impacts soundproofing (no acoustic bridges). Barlinek recommends the that the minimum value for the underlay is PC≥0.5mm.

The following underlays in Barlinek’s offer meet these requirements:

• EKO under-floor tile

• Cork mat

• FixMat SOUND 2.1SD

Protection against residual moisture in the substrate (SD – water vapor diffusion resistance

SD>75

Barlinek recommends the use of underlay with an integrated moisture barrier. The higher the Sd value, the better the floor is protected against moisture. Sd value > 75 m is recommended.

If you choose an underlay without an integrated moisture barrier, it must be provided as a separate, additional layer.

The following underlays in Barlinek’s offer meet these requirements:

• FixMat SOUND 2.1SD

Resistance to loads including dynamic load (DL), compressive creep (CC) and compressive strength (CS)

It is very important that the underlay is able to withstand various types of loads for many years of use and does not deform or lose its properties. The underlay is subjected to daily loads due to walking, standing furniture, etc.:

• DL – dynamic loads due to walking

• CS – compressive strength due short-term load

• CC – compressive creep due to long-term static load, e.g. furniture placed on the floor

Barlinek recommends the following requirements for underlay depending on the place of their installation:

| Minimum requirement | Higher requirement ** |

| DL ≥ 25,000 cycles | DL ≥ 100,000 cycles |

| CS ≥ 150 kPa | CS ≥ 220 kPa |

| CC ≥ 20 kPa | CC ≥ 40 kPa |

| The following underlays in Barlinek’s offer meet these requirements:

· EKO under-floor tile: · Cork mat · FixMat SOUND 2.1SD · EXTREME 1.5 |

The following underlays in Barlinek’s offer meet these requirements:

· FixMat SOUND 2.1SD · EXTREME 1.5 |

**For floating installation of the Barlinek herringbone floorboards an Optilock, regardless of the place of installation, we recommend an underlay with a minimum DL ≥ 100,000 cycles and CS ≥ 220 kPa.

Important: 10 kPa ~ approx. 1 t/m²

Impact sound insulation (IS)

An underlay for wooden layered floors should significantly reduce the sound of impact. The noise that results from walking in a room on a higher floor is referred to as the impact sound.

Barlinek recommends the following requirements for underlay depending on the place of their installation:

| Minimum requirement | Higher requirement |

| IS ≥ 14 dB | IS ≥ 18 dB |

| The following underlays in Barlinek’s offer meet these requirements:

· EKO under-floor tile · Cork mat · FixMat SOUND 2.1SD · EXTREME 1.5 |

The following underlays in Barlinek’s offer meet these requirements:

· EKO Under-floor tile · FixMat SOUND 2.1SD · EXTREME 1.5 |

Reflecting Walk Sound (RWS) reduction

The noise generated in the room as a result of footsteps is referred to as reflecting walk sound. By using suitable underlays, the noise level in the room can be effectively reduced. Unfortunately, the standard test for this parameter is under development and currently there is no valid test method. We know from practice that the higher the underlay density, the greater the noise reduction in the room.

Barlinek recommends underlays reducing the noise level in the room:

• FixMat SOUND 2.1SD

• EXTREME 1.5

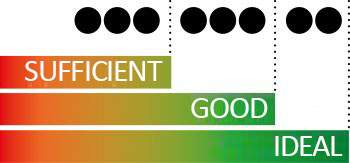

Each underlay offers different properties when used under a wooden floor, so choose the underlay according to your needs:

| A COMPARISON OF BARLINEK UNDERLAYS |  |

| APPLICATION | FixMat Sound | EXTREME 1.5 | Mata korkowa | Płyta Eko |

| Floor soundproofing | ||||

| Room soundproofing | ||||

| Thermal conductivity | ||||

| Vapour barrier | ||||

| Load resistance | ||||

| Subfloor levelling | ||||

| Thermal insulation |

*These guidelines should be considered as recommendations of the manufacturer of wooden layered floors. The requirements for underfloor underlays are developed and publish by The European Federation of the Parquet Industry (FEP) in the technical bulletin of February 2022.